Litšepe tse khethehileng li entsoe ka mokhoa o nepahetseng ho etsa ntlo ea ho phunya.

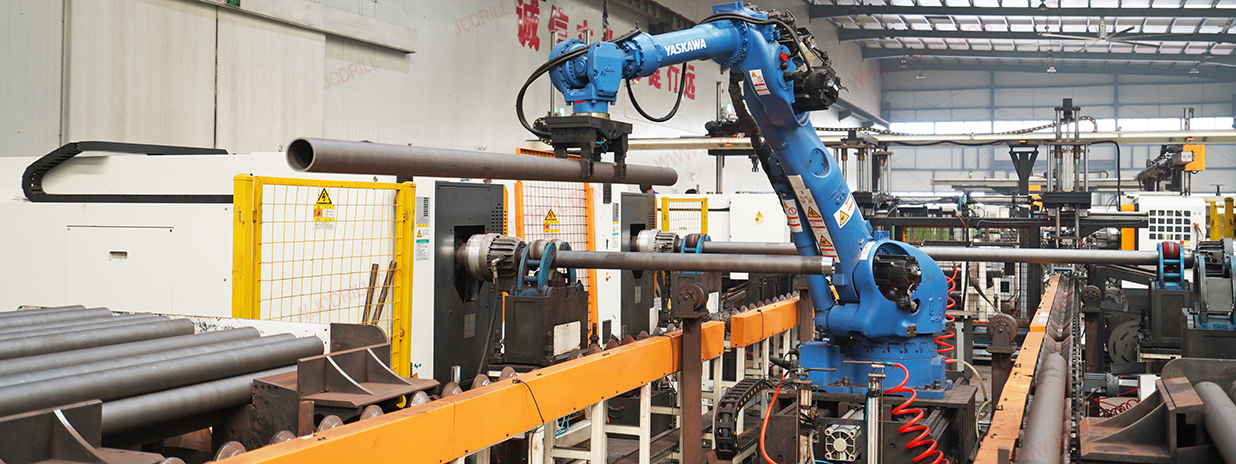

Re na le lisebelisoa tse 17 tsa litsi tsa mochini tsa CNC tse kenyelletsang 3m gantry machining center, 6163 orizontal boring lathes, 400 set CNC lathes, 39 set CNC milling machines, 15 set deep hole machine ,31 sets universal cylindrical grinding, le 6-brand 2 sets 2.

Li-alloys li sebelisa likhoebo tse tsebahalang tsa lapeng ho ts'ehetsa, ho netefatsa hore ts'ebetsong ea ho cheka mafika, ho hanyetsa ka botlalo ha lihlahisoa ho feta maemo a indasteri.Ha ntlo le motsoako li kopana, re sebelisa lesoba le le leng, teko ea leino le le leng, ho etsa bonnete ba hore sehlahisoa se sebelisoang, ha se hlahe meno, ho tšolla ntho e makatsang.

Ka lisebelisoa tse ntle tsa ho penta, lisebelisoa tsohle tsa rona tsa ho cheka ka ho hloekisoa ka thata holim'a metsi, ho lokisoa, ho penta, le ho hloekisoa, pente ea boleng bo holimo e fana ka lisebelisoa tsa ho phunya tšireletso khahlanong le mongobo le oxidation nakong ea lipalangoang le ho sebetsa.

Re ka phethahatsa tlhokahalo e khethehileng ea bareki bakeng sa ho qhibilihisa, ho etsa tšepe e khethehileng e khethehileng, le tšepe ea tšepe holim'a mochini o ebolang ka lathe e se nang bohareng, ho hlahloba ka ho lemoha liphoso tsa ultrasonic ho netefatsa boleng ba lisebelisoa tse tala.

Re ke ke ra etsa li-workpiece tse kholo feela empa hape re ka sebetsana le lihlahisoa life kapa life tsa tšepe ka mokhoa o tloaelehileng, ho futhumatsa, ho chesa, ho tima oli le ho tima letsoai, kalafo ea holim'a metsi, ho fifala le kalafo ea naetrojene.Re na le boiphihlelo bo bongata le taolo e nepahetseng mabapi le kalafo ea mocheso, mochini o batang le kalafo ea holim'a metsi, e le hore li-workpieces li ka kopana le boleng bo holimo ha bo sebelisoa.

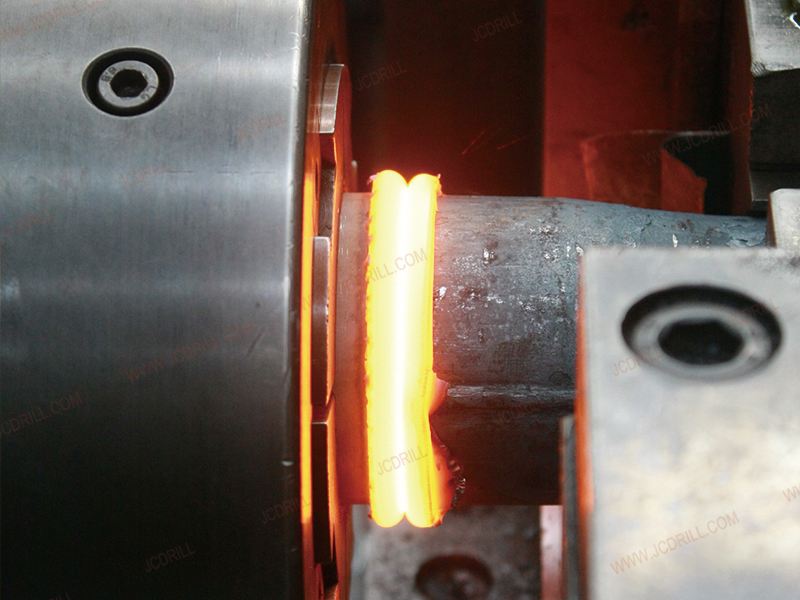

Ho etsa bonnete ba hore boleng ba tjheseletsa ea liphaephe tsa ho cheka, ka theknoloji e tsoelang pele ea tšubuhlellano ea likhohlano le likhomphutha ho bona methati ea ho tjheseletsa. U sebelisa mocheso oa welding le deformation e holimo, sebopeho sa weld se etsoa kalafo ea bobeli ea khale ka lisebelisoa tse tiileng tsa ho tima.Etsa hore sebaka sa ho cheselletsa se be setle 'me se be makhethe, 'me u ntlafatse sebaka sa phala ea ho cheka.

Re amohela liphutheloana tse matla le tse loketseng, tse sa tiiseng feela tšireletso ea lisebelisoa tsa ho phunya nakong ea lipalangoang, empa hape li thusa ho tsamaisa le ho sebetsana le basebelisi.Liphutheloana tsohle tsa sehlahisoa li ka etsoa ho latela litlhoko tsa mosebelisi.